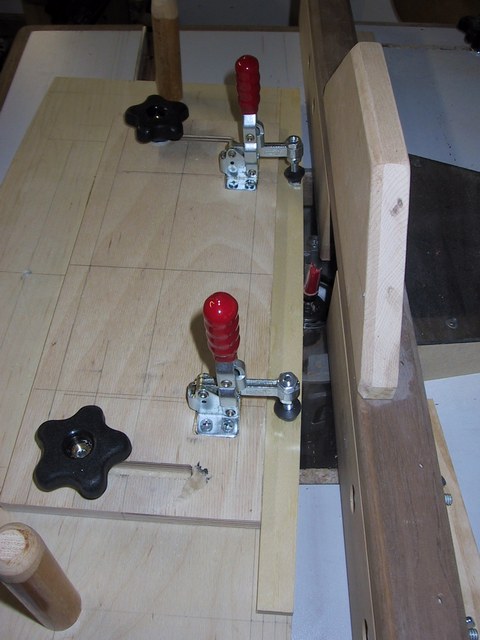

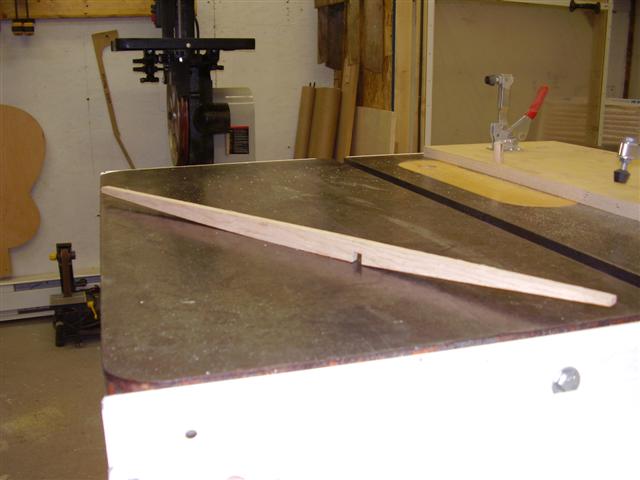

I too found that the flex was a problem. I took some thin maple stock and made a template for 15' and another for 25' radii.

When it comes time to shape the brace, I simply mark the brace to the correct radius using the template and then I take it to my bench top sander removing the extra material.

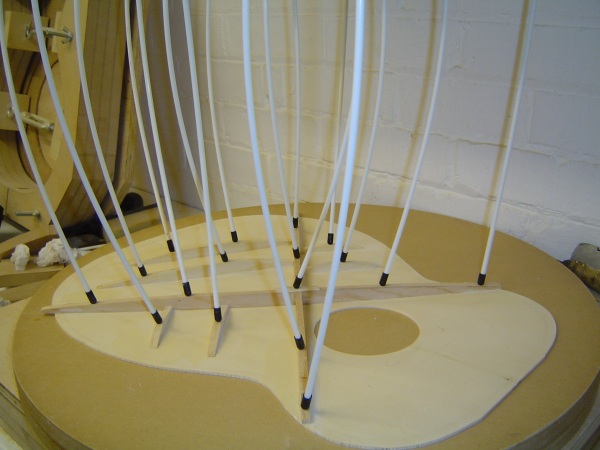

Then I'll finish it off in the sanding dish. I found this method cut down the sanding/time by a significant amount. I then check the accuracy and fit by sitting the brace in the 'gluing' bowl. I don't stop until it's 'air tight'...

What you listening to?

.

.